In many components a temperature rise is an indication of an approaching malfunction. After this malfunction has taken place, the necessary thermal inforation is no longer available as all parts have cooled down. This makes trouble shooting a lot more difficult.

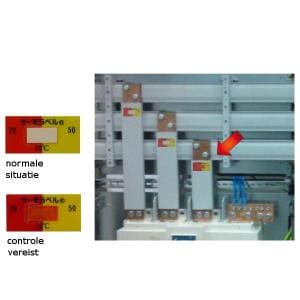

T Service introduces a low-cost, low-tech diagnostic tool to tackle this issue: Thermolabels. These adhesive temperatue-sensitive labels can easily be placed onto all critical components (e.g. relays, bearings, engines or gear casings). As soon as a certain temperature is reached, the label irreversably changes its color. This allows you to view all thermal information 24/7, even after a shutdown. Trouble shooting can thus be carried out faster and the up-time of your equipment will increase.

Thermolabels can be used for preventive, corrective and condition based maintenance. They can even be applied to components for which regular condition monitoring (using e.g. vibration analysis or thermographic inspection) cannot be used due to their location or because of a safety distance. They can also be used for temperature control in many manufacturing processes (such as flow monitoring in pumping palm oil, or as a level gage in a brewing tank).

T Service, the specialist in temperature and technology, is the European distributor of Thermolabels of Japanese brand NGK. These labels are known for their exceptionally long lifespan and their high quality, while they are still inexpensive.